smitool

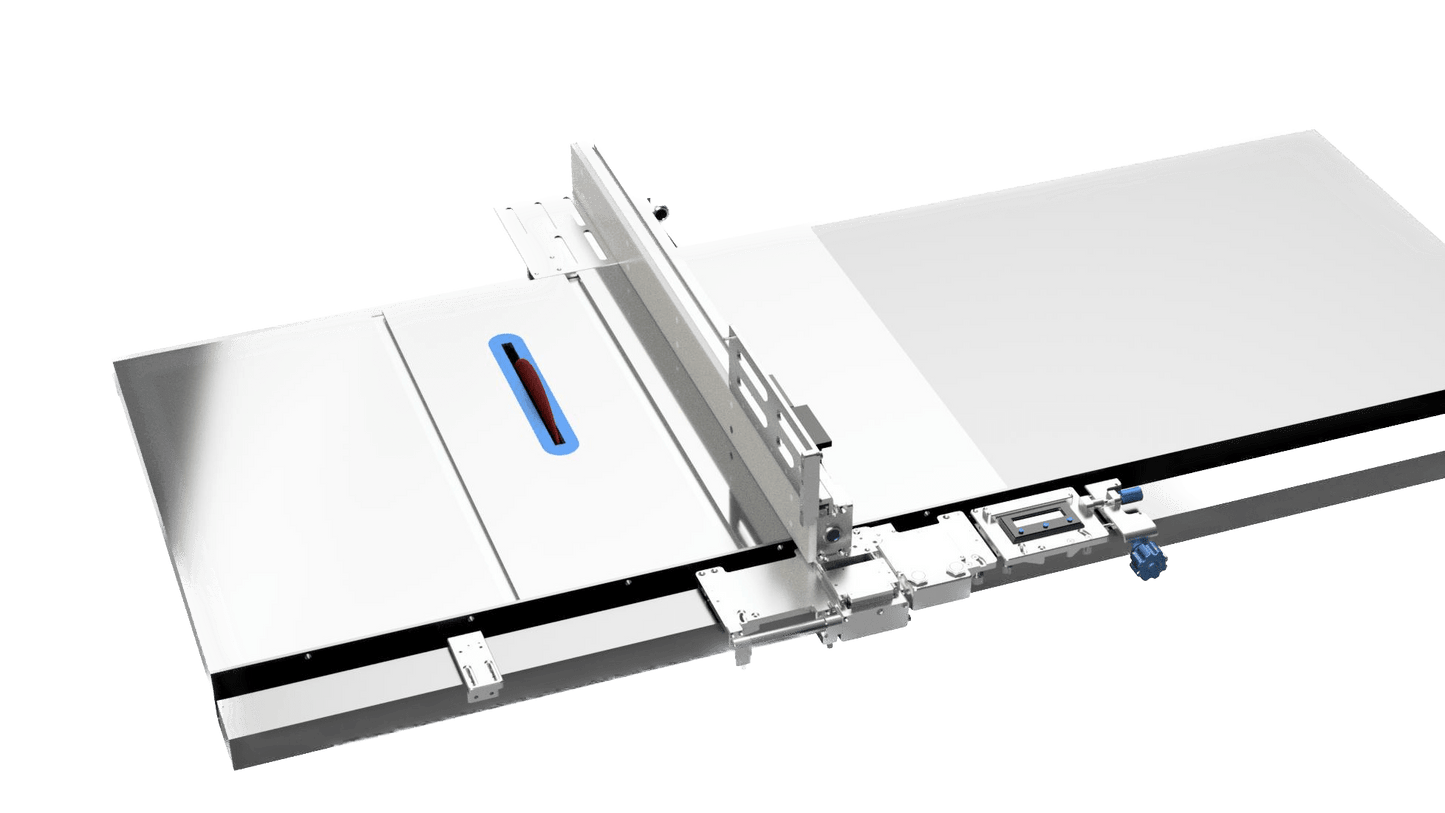

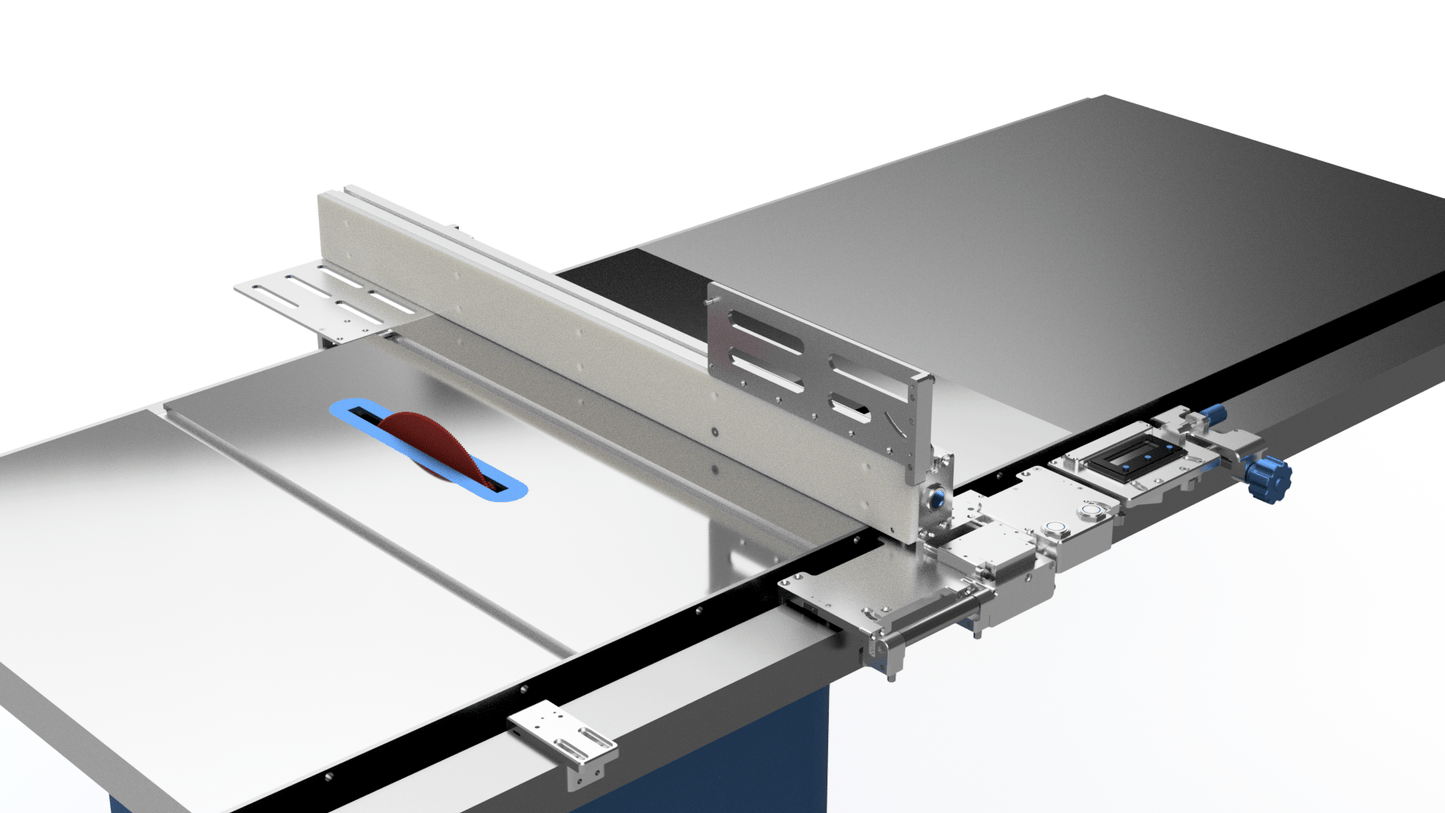

Auto-Easy Table saw Fence( New automatic fence, coming soon)

Auto-Easy Table saw Fence( New automatic fence, coming soon)

Couldn't load pickup availability

Share

More:

FAQ

Q&A:

1. Why is installation emphasized across the saw blade for the table saw, while on the router table, it's emphasized at the rear of the bits?

- The router table emphasizes the rear installation of the bits due to their small size and the positioning of the two wheels behind the bits. This setup ensures that wood advances in a straight line throughout the process, maintaining stability and providing ample space for setting up the router table.

2. Why use dual motors?

- Dual motors are used to address issues encountered in earlier single-motor designs. The single motor setup had problems such as instability, unbalanced design, limited safety space around the saw blade, excessive weight, high noise, and a high failure rate. The dual motor design, with customized motors and gearboxes, offers advantages like compactness, reduced weight, increased driving force, a larger safe space around the saw blade, stable operation, and an extremely low failure rate.

3. Why can the riving knife be moved?

- The riving knife has two main functions: preventing the saw kerf from closing and clamping the blade and guiding the cut wood to stay close to the fence. When using Auto-Cut, the saw blade is positioned between the front and rear wide wheels, The wooden board is secured at all four corners, preventing the boards from clamping the saw blade. As for guiding the board along the fence, that's its strong suit..

4. Why is the laser guide line height about 1/2 inch higher than the board?

- Determining the appropriate height for the saw blade to protrude above the board is subjective and varies based on preferences and safety considerations. Some recommendations lean towards more blade exposure for safety, while others suggest showing more board surface (e.g., about one inch) for better cut quality and less blade wear. A height of about 1/2 inch is set for the laser guide line to strike a balance.

5. Why does the box sometimes move with difficulty after the electromagnet is powered off?

- The product utilizes a robust built-in electromagnet to secure the box to the table saw top. The iron top of the table saw may retain temporary magnetization even after the electromagnet is powered off. In such instances, the box may initially resist movement. Applying additional force should enable it to move freely afterward.

6. My table saw top is integrated with a router table, and the current rail length doesn’t reach the far left side—what should I do?

- No worries—we’ve handled this situation many times. Before placing your order, just email us the exact distance from your saw blade to the far-left edge of your table, and we’ll include a custom extension kit to ensure full coverage for your setup.

7. Will it fit my table saw?

-Our system is compatible with most North American standard 10-inch cabinet or contractor-style table saws, especially those with cast iron tops. Since some saws may vary slightly in dimensions or fence configurations, feel free to contact us with photos or measurements—we’re happy to confirm compatibility for you.

8. Is it plug-and-play? Do I need technical skills to install it?

-In most cases, yes—it’s plug-and-play. Installation is straightforward, with no wiring modifications required. As long as you’re comfortable with basic table saw operations, you’ll be able to install it with ease.

9. Does the system require regular maintenance?

-Very little. The product is built for long-term use and is virtually maintenance-free under normal conditions. Just keep the components clean and free of sawdust. We recommend checking the screw tightness every few months to maintain consistent precision and safety.

10. What if I need to replace a part in the future?

-The system uses a modular design, and all replaceable components—like motors and wheel assemblies—can be swapped individually. We offer official replacement parts and can assist you remotely with diagnostics and installation if needed.

-11. Is there a warranty?

Yes. All Smitool products come with a 180-day limited warranty, covering manufacturing defects and hardware issues under normal use.

-12.Will I be charged customs duties in the U.S.?

No. We ship directly from Canada under the USMCA (United States-Mexico-Canada Agreement).

There are no import duties or taxes for U.S. customers, even for orders over $800 USD.

Your package will be delivered like any standard shipment — no surprise fees or hidden charges.

All tools are clearly declared as Canadian-made woodworking equipment, ensuring smooth customs clearance.

If you have any concerns, feel free to contact us.

So far, none of our U.S. customers have ever been charged duties.

Warranty & Support

Great Value. Worry-Free Ownership.

When you choose Smitool, you're not just buying a tool—you're investing in long-term reliability, easy maintenance, and peace of mind. Here's why we stand behind that promise:

1. 30-Day Hassle-Free Returns

If you're not satisfied with your purchase, you can return it within 30 days—no questions asked and no hidden conditions.

2. 180-Day Product Warranty

All Smitool products come with a 180-day limited warranty covering hardware defects and manufacturing issues under normal use.

3. Built for Long-Term Performance

To ensure your tool performs reliably for years to come, we've carefully engineered every detail with durability and serviceability in mind:

high-grade metal materials, including stainless steel and 6061 aluminum alloy, for structural strength and a professional finish. Plastic is used only when absolutely necessary to reduce aging and wear.

modularity and bolt-on connections, avoiding sealed or fully integrated systems. This means that any wear-and-tear parts can be easily replaced when needed—no special tools or technician required.

replacement part shipping and remote support, so you can restore or upgrade your system quickly and with confidence.

Buy once. Use for years. Count on it.

Shipping & Return

🚚 Ships from Canada via UPS

📦 3–5 business days to anywhere in the U.S.

✅ Worry-free support & returns included!

Technical Data

Technical Data:

- Driving speed: 0-27 feet per minute

- Maximum output power: 1/2 hp

- Power supply: Input AC 110-220 V, Output DC 24 V, 15A

- The maximum cutting thickness available for a table saw (when the drive wheel is used vertically) is 50mm/2 inch.

- Maximum usable table saw size: 22.5 inches (570mm) from the blade to the left edge of the tabletop. Please measure your table saw size before purchasing.

About the Auto-Cut Kickstarter: Challenges & Evolution and More

In January 2024, we launched the Auto-Cut project on Kickstarter. It was a bold move. Yes, it was a success—we gained the trust of 191 amazing backers. But in many ways, it wasn’t a complete success—we faced tremendous challenges along the way.

We understand that you may come across some negative comments on Kickstarter. And we understand the frustration—most of it stemmed from the conflict between our commitment to uncompromising quality and the realities of scaling up manufacturing. To ensure the product was truly reliable, we asked our suppliers to start over multiple times, which caused delays. And yes, there were times when we didn’t respond to backers as quickly as we should have. We take full responsibility for that.

As an independent creator, we handled everything ourselves—from design, prototyping, and refinement to production and support. We never abandoned a single promise. More importantly, we refused to deliver a half-baked concept. We wanted to ship a finished, fully functional product—something people could actually use and rely on.

Eventually—though it took longer than we hoped—we fulfilled that mission. All orders have now been shipped (except for a few backers who never provided a valid address). Every customer in the U.S. and Canada received their Auto-Cut, and even among our most demanding Kickstarter supporters, no one has questioned the product’s functionality or reliability. On the contrary, we’ve received genuine praise from both hobbyists and professionals.

💬 For example, one long-time user—an experienced woodworker who has worked with traditional feeders for years—has been using Auto-Cut heavily for nearly two years. Just last month, he reached out to us and generously shared two short video clips showing Auto-Cut in action—cutting large panels and operating smoothly on a shaper. We’re deeply grateful for his feedback.

This journey has taught us a lot, and made us even more grateful for every customer’s trust. Today, Auto-Cut is no longer a concept or a Kickstarter slide deck. After over a year of refinement and field use, it has evolved into a stable, reliable, and market-proven automatic feeder for woodworking.

We believe Auto-Cut can bring real value to your shop, making your workflow safer, faster, and more efficient. We’d love to welcome you as part of the Auto-Cut community—and if you ever have questions or feedback, we’re here for you.